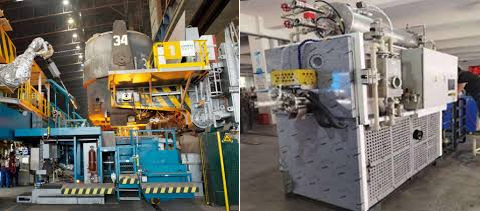

Automated Robotic Assembly System for

Continuous Casting Crystallizer

Product Category

Application Areas

Continuous Casting Machines (CCM)

Mold Assembly Automation

High-Temperature Molten Steel Handling

Integration with Flow Control Systems

Metallurgical Refining Processes

Product Advantages

Precision Engineering

Custom-designed to fit specific CCM requirements.

Optimized heat transfer efficiency for rapid solidification.

Automation Integration

Compatible with robotic mechanisms (e.g., nozzle changers, slide gates).

Reduces manual intervention and operational errors.

Durability & Longevity

Constructed from high-grade refractory materials.

Extended service life under extreme molten steel environments.

Cost Efficiency

Minimizes downtime through modular design.

Lowers maintenance costs with durable components.

FAQs

Q: What makes your crystallizer assembly stand out?

A: Our system combines advanced robotics with metallurgical expertise, ensuring seamless integration into existing CCM workflows while boosting productivity.

Q: Can it handle diverse steel grades?

A: Yes, our modular design accommodates various steel types and casting specifications.

Q: How does automation improve safety?

A: Automated systems reduce direct human interaction with high-temperature zones, lowering injury risks and ensuring consistent operation.

Call to Action

Ready to elevate your casting efficiency?

Contact our experts:

Phone:+86-15993156766

Email:harryjin@ghongsteel.com

Live Chat:Available on our website