Precision Stopper Rod Solutions

for Optimized Steelmaking

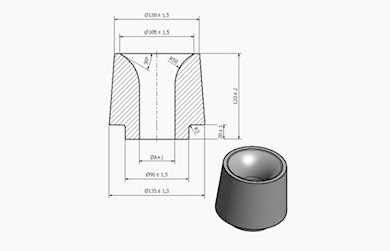

Product Category

| Primary Category | Refractories for Flow Control |

| Subcategory | Stopper Rod |

| Material Options | High-Density Alumina |

| Silicon Carbide | |

| Custom Alloy Composites | |

| Applications | Continuous casting tundish systems, ladle shrouds, submerged entry nozzles |

Application Areas

Product Advantages

Production Boost:

Reduce downtime with 30% longer service intervals

Quality Assurance:

±1% flow rate consistency ensures defect-free castings

Safety Protocol:

Automated emergency release mechanism

Cost Efficiency:

25% lower maintenance costs vs. conventional designs

FAQs

Q1: What makes GH stopper rods superior to competitors?

A: Proprietary surface hardening treatment extends service life by 40%.

Q2: Can stopper rods be customized for unique tundish configurations?

A: Yes, our modular system accommodates all major tundish designs.

Q3: What certifications do your stopper rods hold?

A: ISO 9001, CE compliance, and metallurgical industry-specific certifications.

Accelerate Your Next Project

Henan Genghong Industrial Co., Ltd.

Email: sales@ghongsteel.com

Phone: +86-15993156766

Address: Zhengzhou,Henan,China