High-Temperature Resistance Ladle Shroud

for Steelmaking Efficiency

Product Category

Application

Ladle Shrouds are critical components in the steelmaking industry, specifically designed for:

Secondary Refining

Prevent molten steel reoxidation and non-metallic inclusion contamination

Continuous Casting

Ensure stable flow control in tundish and mold systems

Specialty Alloys

Withstand extreme temperatures (up to 1800°C) for high-grade steel production

Energy Efficiency

Reduce thermal energy loss during casting processes

Product Advantages

Our Ladle Shrouds offer several significant advantages that make them stand out in the market:

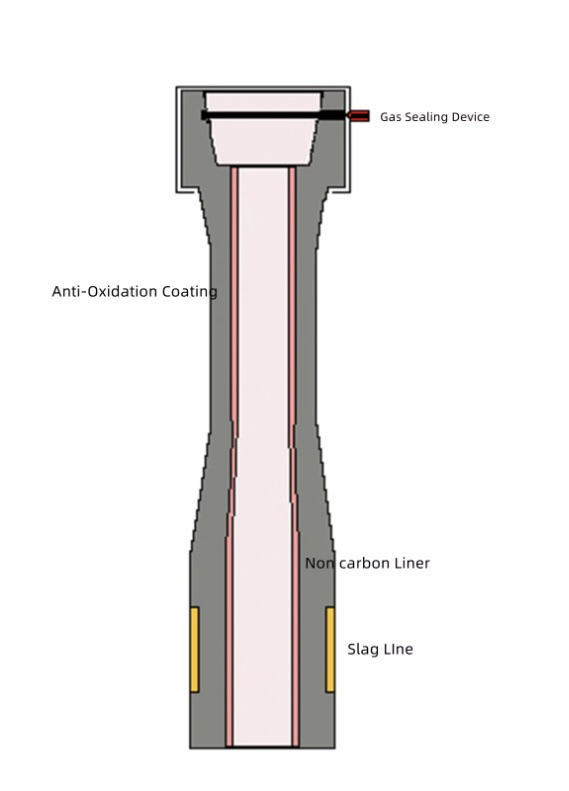

Superior Refractory Materials:

Crafted from high - quality refractory materials, our ladle shrouds have excellent resistance to high temperatures, thermal shock, and chemical corrosion. This ensures a long service life, reducing the frequency of replacement and minimizing production downtime. The advanced materials also help in maintaining the shape and integrity of the shroud under harsh casting conditions, providing reliable performance throughout the casting process.

Enhanced Flow Control:

The design of our ladle shrouds is optimized to provide precise control over the flow of molten steel. The smooth internal surface and carefully engineered shape reduce turbulence and splashing, ensuring a stable and consistent flow. This helps in improving the quality of the cast products by reducing the formation of surface defects and internal inclusions.

Improved Steel Quality:

By preventing the oxidation and contamination of molten steel, our ladle shrouds contribute to significant improvements in steel quality. The reduced absorption of gases and inclusions results in cleaner steel with better mechanical properties, such as higher strength, ductility, and toughness. This makes our shrouds a valuable asset for steel producers aiming to meet the high - quality standards of modern industries.

Customization Options:

We offer a high degree of customization for our ladle shrouds. Whether it's adjusting the size, shape, or material composition, we can tailor the shrouds to meet the specific needs of our customers. This flexibility allows steel producers to optimize their casting processes and achieve better production efficiency and product quality.

Frequently Asked Questions

Q: How does the choice of ladle shroud material affect its performance?

A: The material of the ladle shroud significantly impacts its performance. High - quality refractory materials with excellent thermal shock resistance and wear - resistance properties can withstand the extreme temperatures and erosive forces of molten steel, ensuring a longer service life. Materials with good chemical resistance prevent reactions with the molten steel, maintaining the quality of the steel and the integrity of the shroud. Our ladle shrouds are made from advanced refractory materials carefully selected to provide optimal performance in various casting conditions.

Q: What is the typical lifespan of your ladle shrouds?

A: The lifespan of our ladle shrouds depends on several factors, including casting conditions, steel grade, and operating practices. Under normal casting conditions, our standard ladle shrouds can be used for [X] to [X] casting heats, while our high - performance shrouds, due to their superior materials and design, can last for [X] to [X] casting heats. However, with proper maintenance and in less demanding applications, the lifespan can be extended.

Contact Us

If you are interested in our Ladle Shroud or have any questions, please feel free to contact us. Our team of experts is ready to assist you and provide you with the best solutions.

Email: sales@ghongsteel.com

Phone: +86-15993156766

Address: Zhengzhou,Henan,China